Papergraphics Hands-On Preview of the Revolutionary Flexa Katana Cutter

As Flexa's lead UK distributor, Papergraphics was the first to experience their groundbreaking new Miura Katana automatic cutter. Named after the two-handed Samurai blade, this machine redefines precision high-speed cutting.

Our Head of Technical Shares his Thoughts

"It's all about the dual shearing blades, angled perfectly to cut without leaving white edges—something businesses have been crying out for." Says Papergraphics head of technical, Graham De Kock. "I was fortunate to visit Flexa's headquarters in Italy and saw its effectiveness first-hand. The results are impressively accurate, even at high speeds."

Flexa Miura Katana Review

Flexa Miura Katana Review

Flexa Miura Katana Review

Flexa Miura Katana Review

Flexa Miura Katana Review

Power, Precision, and Pace

At the core of the Katana lies its ultra-fine dual digital positioning system, ensuring blades are always aligned with pinpoint accuracy. This innovation eliminates common issues like misalignments and uneven edges, saving valuable production time. Its specialist dual shearing blade design guarantees precise cuts, even on complex media such as natural and synthetic fabrics.

Whether you're tackling intricate patterns that demand perfect alignment or working with challenging materials, the Katana delivers flawless results, making it an invaluable tool for print businesses aiming to exceed expectations.

"The Katana is remarkably quick," Graham adds. "It's capable of handling outputs from multiple printers with ease. While it can be optimised for inline systems, its true capabilities shine when used offline."

To support its rapid cutting pace, the Katana features a dual traction roller system, which prevents rippling and creasing during operation. Even delicate or textured materials like wallpaper glide through seamlessly, ensuring smooth and efficient workflows without interruptions.

Empowering UK Print Businesses

For Papergraphics, the Flexa Katana is more than cutting-edge technology—it's an opportunity to empower UK businesses by enhancing their production capabilities.

Graham Sums It Up!

"This is Flexa at its best. Every aspect of the Katana has been engineered with the end user in mind. It's a considerable investment, but one that pays for itself quickly through its fast, accurate, and reliable performance. I've never seen this level of innovation at this price point before."

As the UK's key distributor for Flexa, Papergraphics is proud to bring the innovation of Flexa's High-Precision Miura Katana XY Cutter to our customers. To discover how the Flexa Katana can transform your production workflows, contact us today at 0345 1300 772.

What the manufacturer says:

Overview

Miura Katana — the new automatic XY cutter for wallpaper with vertical cutting correction.

The machine is equipped with a revolutionary cutting system (patent pending) that allows the cutting of the wallpaper panels, avoiding the white line visible at the junction point once they are coupled.

This exclusive technology removes the need for touch-ups to eliminate unpleasant white lines during installation (which are very visible on prints with dark colours).

The double sensor of the automatic vertical cutting correction achieves a reading accuracy of 0.05 mm, making it ideal for cutting wallpaper and ensuring perfect pattern joints.

The lengthwise shear cutters have a high-resolution digital display that indicates their exact positioning. The fine positioning of the cutting blades also allows for a high-quality finish cut—a detail that makes the cut even more precise!

The automatic cutter is also suitable for many other flexible media rolls.

The Miura Katana can be connected to the internet network for remote assistance for fast and efficient diagnostics.

The perfect wallpaper cut without "white lines" at the junction point.

No more misalignment: Maximum cutting precision thanks to the two edge control sensors that read the line longitudinally printed along the entire length of the roll. The reading accuracy of the sensor is 0,05 mm—result: perfect joints of patterns and designs on the wall.

No more creasing: The dual traction rollers ensure the paper remains taut, preventing wrinkles.

No more white lines: The new innovative cutting system (patent pending) with lengthwise shear cutters allows a perfect cut, avoiding the “white lines” at the junction point once the tiles are coupled. Each blade is motorised.

No more touch-ups: Our new exclusive technology removes the need for touch-ups, eliminating unpleasant white lines at junction points during installation.

You don't need to control the match of the patterns after cutting. Thanks to the two edge control sensors, the machine maintains high-quality standards.

Zero mistakes: Each lengthwise shear cutter has a high-resolution digital display that indicates the exact positioning.

High-performing: The cutter combines horizontal and vertical cutting and cuts one 50-meter roll in less than 5 minutes.

It can operate as a stand-alone unit, in line with a printer or Flexa unwinders, starting from a jumbo roll with a maximum weight of 400 kg and a diameter of Ø 600 mm.

Zero waste cutting: Each cutting unit includes fine positioning of the blades for micro-adjustments, resulting in perfectly cut wallpaper.

Long-term reliability: The cutting units are mounted on a linear recirculating ball bearing system, which allows for exact positioning and ensures long-lasting durability.

Intuitive settings of the cut parameters thanks to the prominent touchscreen display.

Three operation modes: 1. crop mark, 2. custom (sheeting), 3. manual. Miura can trim different lengths from the same printed roll.

Smart remote service: The Miura Katana can be connected to the internet network for remote assistance for fast and efficient diagnostics.

Made in Italy: designed and manufactured in Italy with Flexa guarantee of pre-sales, after-sales and maintenance.

Materials the automatic Miura Katana can cut!

Waterproof, fibreglass, TNT, viscose, linen, Alcantara, woven plant fibres, organic nonwoven fabric made with plant-based raw materials, sound-absorbing substrate, wallpaper and many more.

Datasheets

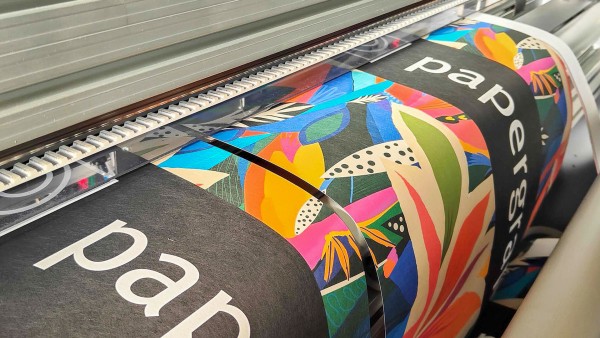

Photos